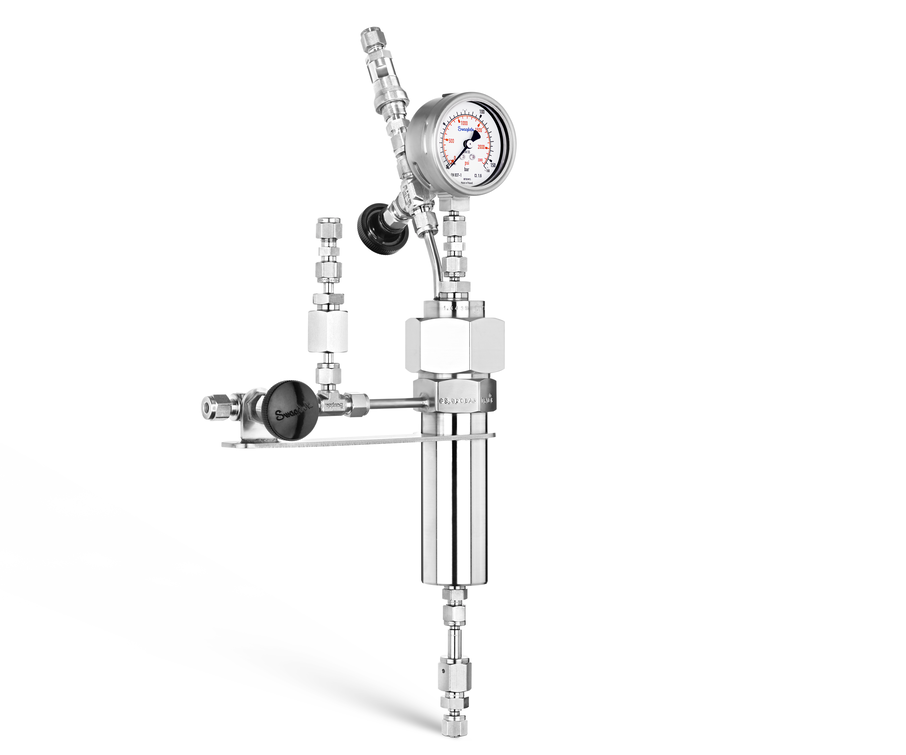

Catalyst reservoir

- Home

- Accessories & Spare Parts

- Accessories

- Catalyst reservoir

Catalyst receiver vessel

This catalyst receiver allows the addition of a heterogeneous or homogeneous catalyst into a reactor, under inert and controlled conditions. Commercial powder catalysts such as activated carbon supported or Raney catalysts have been successfully tested.

- The unit is mounted on top of the reactor and connected to the reactor via a pipe with an inner diameter of xyz. A valve between the auxiliary device and the reactor can be either in open or closed position.

- The reactor is charged with the liquid and the reaction substrate, then closed and finally inerted. In the case of hydrogenation, the inert gas is replaced by hydrogen.

- The catalyst storage vessel is loaded with the catalyst and liquid. During loading, the valve between the unit and the reactor is in the closed position. After charging, the auxiliary unit is inert. In the case of hydrogenation, the inert gas is again replaced by hydrogen.

- The liquid and the reaction substrate are heated to the desired setpoint temperature without a catalyst.

- When the set point has been reached, catalyst slurry can be added with the help of pressure by opening the valve between the catalyst feed vessel and the reactor (pressure in catalyst feed vessel > pressure in reactor)

Specifications

- Vessel volume 100 ml, material WNr . 1.4435 (AISI 316L), design pressure 120 bar, operating pressure 100 bar, design temperature 50°C

- Dimensions vessel ø 52 x 146 mm

- Cover material WNr . 1.4435, ø 44 x 53 mm

- Closure: hexagon nut material WNr. 1.4980

- O-ring seal Viton

- Pressure gauge 0-60 bar, ø 63 mm

- Needle valve for gas supply 1/4

- Bursting disc holder with bursting disc

- Conical bottom outlet 60°

Variants/special features

- Premex, together with an expert in the field of catalysis/reaction technology, has developed two catalyst feed vessels.

- Version A: additional device equipped with a stirrer, which makes it possible to add a heterogeneous or homogeneous catalyst to the reactor. This type allows, for example, the pre-treatment (pre-hydration or modification) of the catalyst before it is added to the reactor.

- Version B: This type is simpler and has no stirring option, but also allows the complete transfer of the catalyst into the reactor.

- Both systems have been successfully tested with commercial powder catalysts (activated carbon supported catalysts, Raney catalysts).